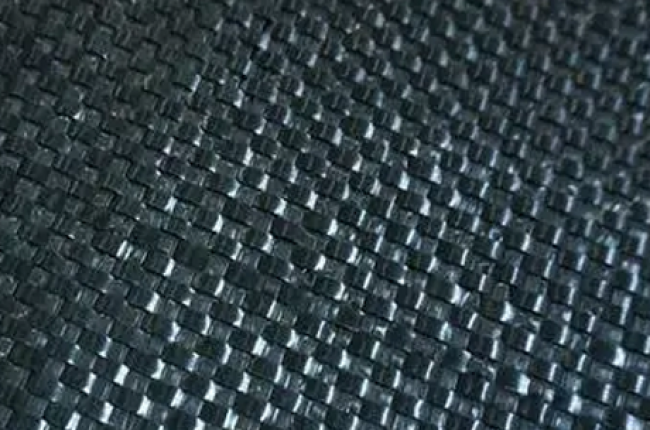

Plastic woven and split film woven geotextile is a kind of plastic woven product produced by drawing and circular weaving with polypropylene or polyethylene raw materials. It is characterized by light specific gravity, acid and alkali resistance, corrosion resistance, high strength, good overall continuity, convenient construction, good combination with soil mass, good permeability, smooth drainage of foundation seepage, and avoiding piping damage caused by soil loss. It can also be sewn into deep-processing products such as soft mattress, irrigation bag and sand tendon bag, which are widely used in water conservancy, highway, railway, airport and other soft foundation treatment and land reclamation projects.

Woven geotextile with plastic woven and split film filament

| Item | DS100 | DS 120 | DS 150 | DS 200 | DS 230 | DS 250 | DS 280 | DS 340 |

| Mass per unit area g/m² | 100±10 | 120±10 | 150±10 | 200±10 | 230±10 | 250±10 | 280±10 | 340±10 |

| Longitudinal breaking strength N/5cm | 900 | 1000 | 1400 | 2000 | 2100 | 2500 | 3000 | 4000 |

| Transverse breaking strength N/5cm | 700 | 900 | 1200 | 1600 | 1700 | 1900 | 2100 | 2800 |

| Longitudinal elongation at break,% ≤ | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Transverse elongation at break (%) ≤ | 20 | 20 | 25 | 25 | 25 | 25 | 25 | 25 |

| Trapezoidal tear strength (longitudinal) n ≥ | 250 | 300 | 450 | 550 | 650 | 800 | 900 | 1000 |

| CBR bursting strength n ≥ | 1200 | 1600 | 2600 | 3600 | 4000 | 4500 | 5200 | 6500 |

| Equivalent aperture o90 | 0.08-0.4 | |||||||

| Vertical permeability coefficient (cm / s) | 10ˉ²-10ˉ⁴ | |||||||

| Width deviation | ≤4±0.05 | |||||||

Product list

Product list

contact us

contact us